Managing Oil Risks in Clean Energy Infrastructure

While solar farms are widely seen as low-impact, sustainable energy sources, they still carry environmental risks. Oil-filled transformers and onsite substations, whilst vital for converting and transmitting the generated power, often contain large volumes of insulating oil. Without proper containment and monitoring, leaks or spills can pose serious pollution risks to soil and nearby watercourses.

Bund water control units form a crucial part of modern solar farm environmental protection strategies. These intelligent systems ensure that bunded areas surrounding transformers or other equipment only discharge clean water — and retain potentially contaminated liquid during spills. This article explores how bund water control units work, why they are essential for solar infrastructure, and how they support regulatory compliance in the UK.

What Are Bund Water Control Units?

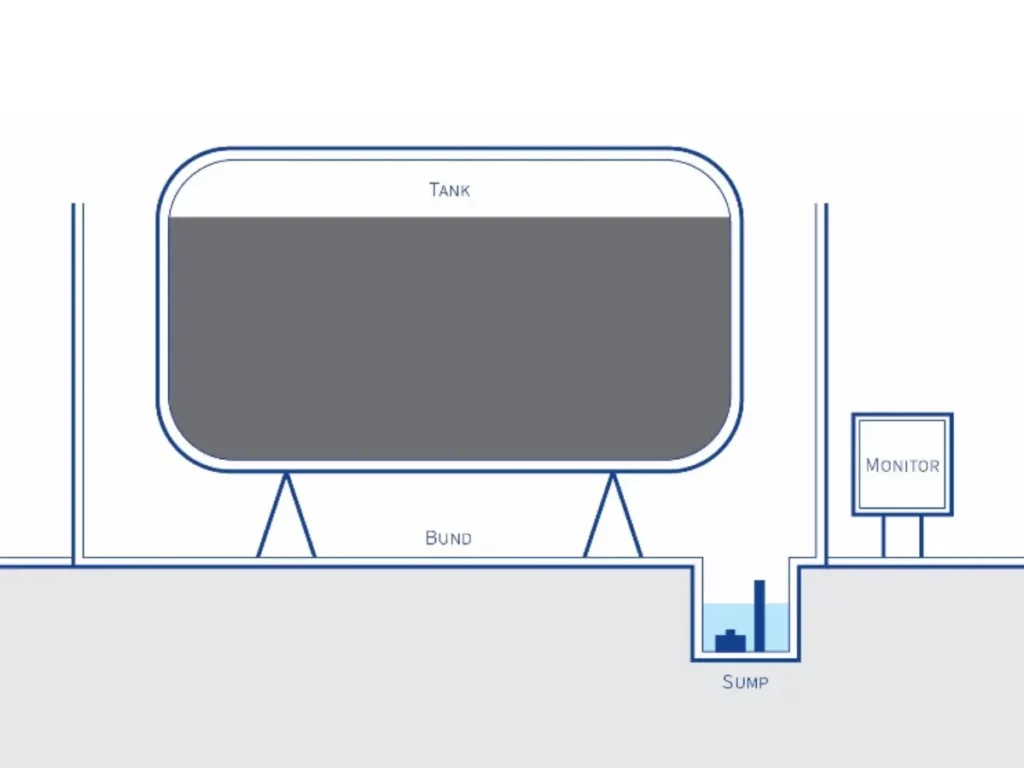

Bund water control units (BWCUs) are automated devices installed within bunded enclosures (the secondary containment structures built around oil-containing equipment such as transformers). These units actively manage water levels within bunds by monitoring for the presence of oil or contaminants and only allowing discharge when the liquid is confirmed to be clean.

Key Functions of Bund Water Control Units:

- Automatic water discharge from bunds when no hydrocarbons are detected

- Alarm-triggered shutoff in the presence of oil contamination

- Remote monitoring and data logging for compliance and audit trails

- Integration with site management systems or standalone operation.

By combining sensors, pumps, and intelligent control panels, bund water control units offer a smart solution that reduces manual intervention and mitigates the risk of accidental pollution.

Why Bund Water Control Units Are Essential at Solar Farms

1. Pollution Prevention

Oil-filled transformers used in substations and grid connections can leak due to failure, damage, or maintenance issues. Rainwater collects in bunds, and if not managed correctly, can overflow, especially if blocked drains go unnoticed. BWCUs ensure that only clean water is released, and potentially contaminated liquids are retained and alarmed.

2. Regulatory Compliance

BWCUs help site operators meet environmental standards and units with data logging and remote alert capabilities also help demonstrate compliance in the event of a regulator inspection or incident review.

3. Labour and Cost Reduction

Manual bund inspections and pump-outs are time-consuming and prone to error. BWCUs reduce the need for routine manual checks, lower labour costs, and prevent expensive clean-up and remediation works following pollution incidents.

4. Site Safety and Emergency Preparedness

Bund water control units are often integrated into broader site protection systems, including:

- Oil sensors and bund alarms

- Remote telemetry and SCADA integration

- Drain closure valves (as part of tertiary containment).

In the event of a transformer failure or fire, these systems provide early warning and enable rapid isolation to contain pollutants.

UK-Specific Compliance Summary

Bund water control units help support compliance with several environmental regulations and standards in the UK:

- Control of Pollution (Oil Storage) (England) Regulations 2001

Requires secondary and (where appropriate) tertiary containment for oil storage over 201 litres. - Water Resources (Control of Pollution) (Oil Storage) (Wales) Regulations 2016

Welsh version of the English oil storage regulations. - Water Environment (Controlled Activities) (Scotland) Regulations 2011 (CAR)

Prevents unauthorised discharge of pollutants from infrastructure, such as bunds. - CIRIA C736

Best-practice guidance recommending the use of automated bund water management systems.

Typical Use Cases on Solar Farms

- Transformer bunds containing oil-filled units

- Battery storage areas with chemical containment needs

- Substation hardstanding areas with potential hydrocarbon runoff

- Construction compounds with temporary oil or fuel storage.

Case Study: Bund Water Control Units Installed at Solar Farms Across the UK and Ireland

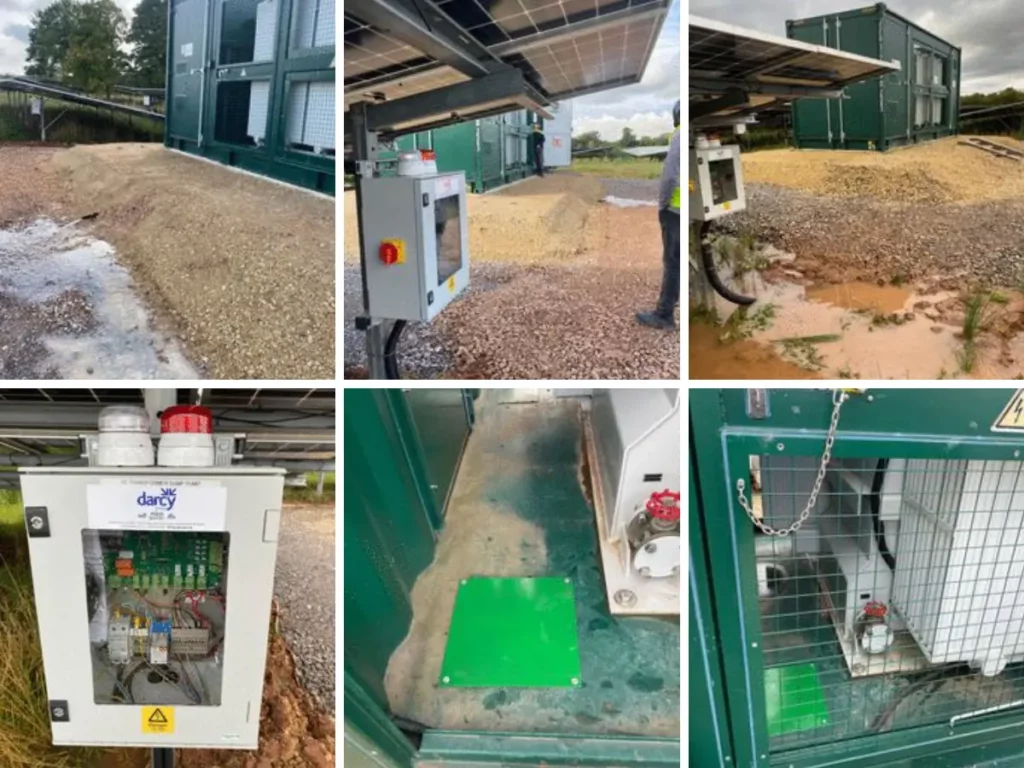

Aquasentry installed bund water control units at several solar farms around the UK and Ireland, with multiple units installed at each site.

At the sites in the Southwest of England, the transformers are sited within a secure container. This container is installed on top of a concrete bund. We installed the bund water control units inside the bund and the control panels at ground level for ease of access. See photos above.

During normal operation, the BWCU removes rainwater from the bund to keep the container at 110% bund capacity, as is required for compliance. If there’s an oil leak from the transformer into the bund, the probe detects presence of oil, shuts off the pump, and sends an alert so that the spill can be dealt with.

The systems ensure continuous, compliant discharge of rainwater while retaining any contaminated liquids for proper disposal — reducing risk and operational burden for the site operator.

Conclusion

Solar farms may generate clean energy, but they still require robust environmental safeguards. Bund water control units are a discreet yet vital part of pollution prevention infrastructure — offering real-time monitoring, intelligent discharge control, and full regulatory compliance. As solar energy expands, so too must the commitment to protecting the environments these installations occupy.

Table of Contents

Sign up for the latest news and offers